OPTICAL COMPONENT MANUFACTURING

Fairfield Crystal Technology provides different types of services that are related to optics fabrication. Many years of our team’s experience in crystal growth and in manufacturing optical components, makes us able to meet specs for some most challenging designs and applications. In the majority of our parts, we are able to reach the highest crystalline material quality and highest surface quality that is set by the industry.

Our Surface Figure range is λ/1 to 2λ and our Surface Quality range is 10/5 to 80/50 S/D. We commonly process a wide variety of optical crystals such as:

- Calcium Fluoride

- Magnesium Fluoride

- Barium Fluoride

- Lithium Fluoride

- Zinc Sulfide

- Zinc Selenide

With the capability to customize any part of our fabrication process, we can make components that are specific to the individual needs of our customers. In order to ensure a good quality and conformance of our optics, we apply different types of tests that include:

- microscope and cross polarizer imaging

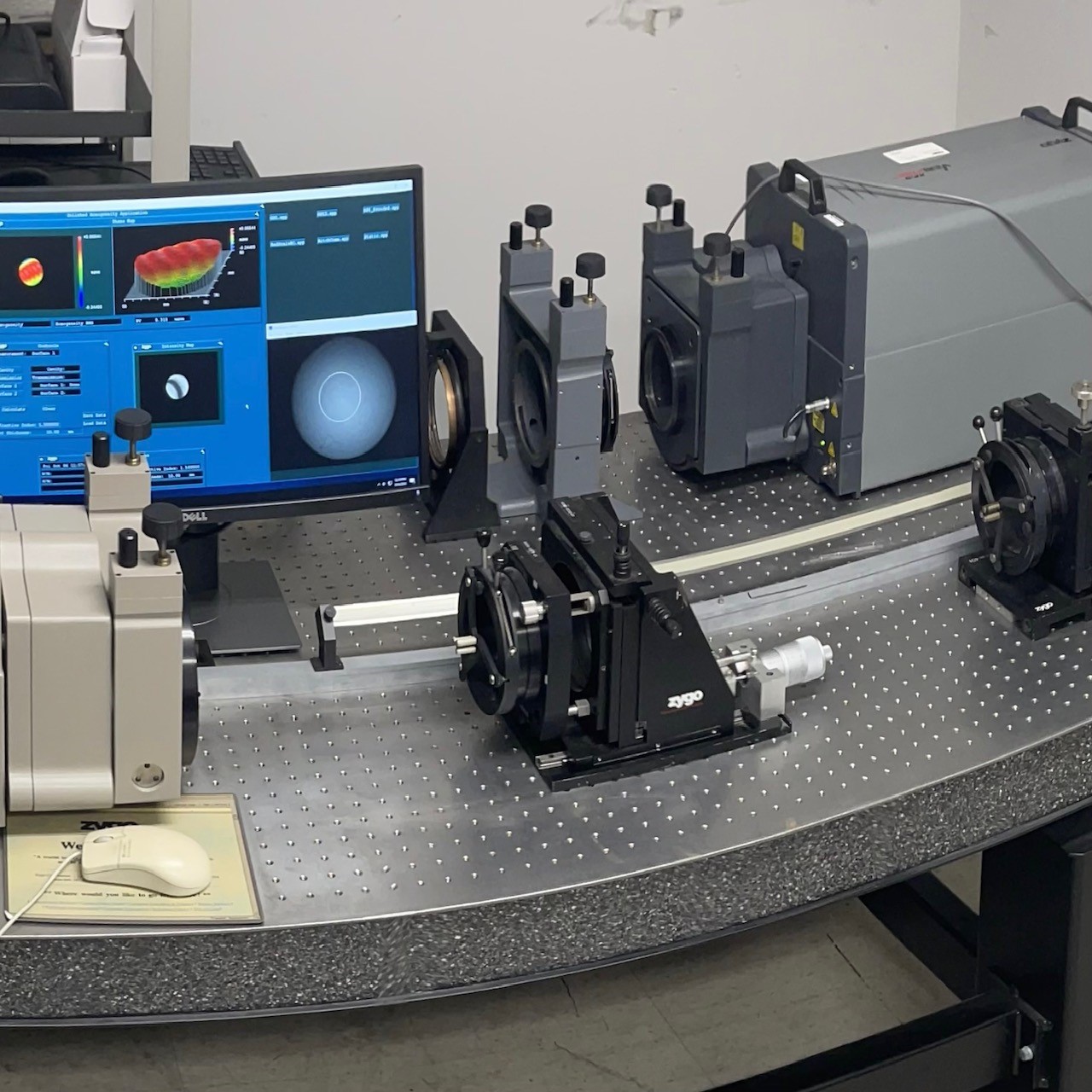

- interferometry on our state-of-the-art multiple Zygo units

- UV- VIS- IR spectrophotometry on Perkin Elmer equipment

- custom laser scattering test

- precision stress birefringence

- as well as a homogeneity measurement

If additional optical testing is required, we can also provide those services, as requested.

Services We Offer

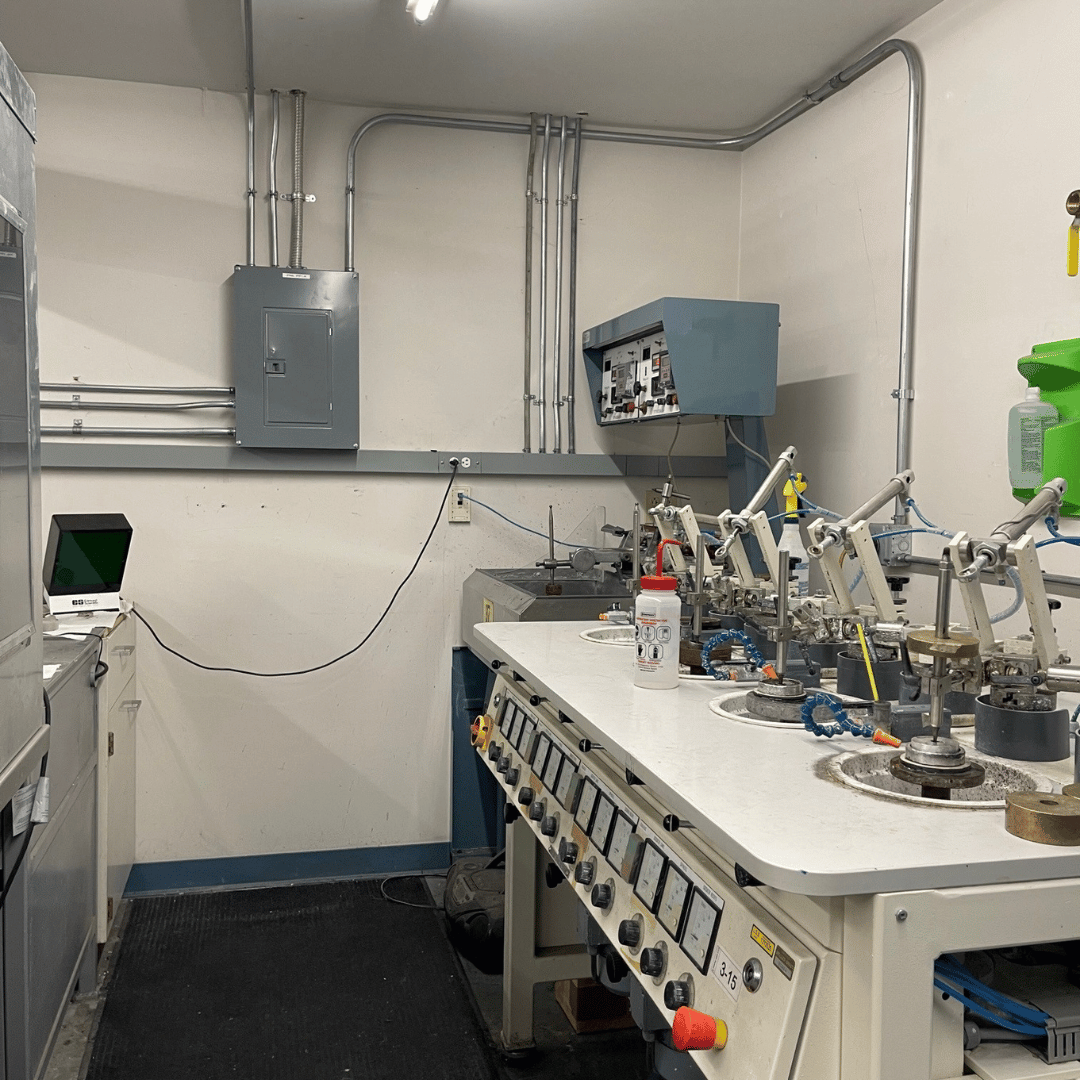

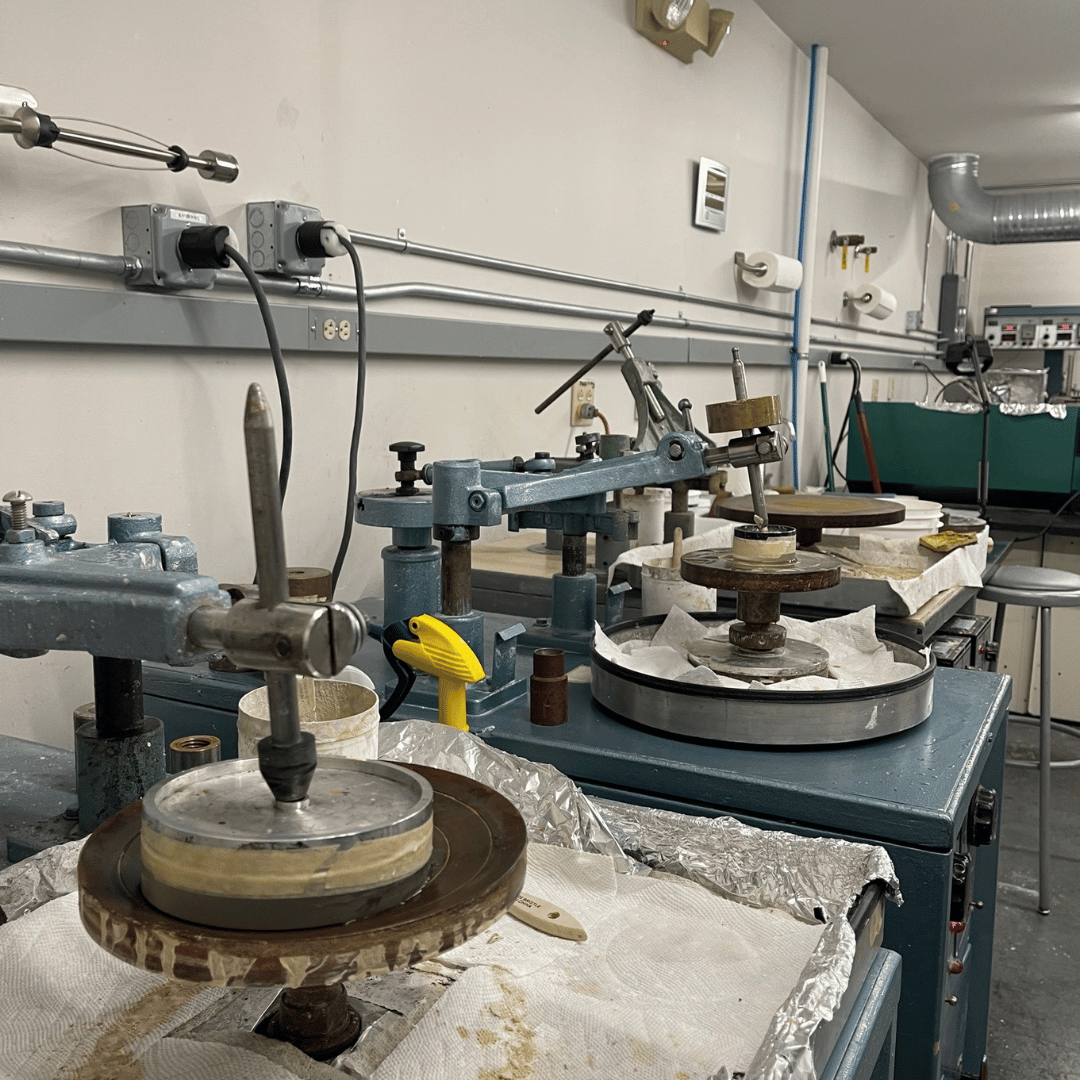

Polishing

- Pitch polishing

- Diamond slurry polishing

- Double and Single Surface

- SF λ/1 to 2λ

- SQ 10/5 to 80/50 S/D

Grinding

- Fine grinding

- Rough grinding

- Custom bevels

Testing

- Visual inspection

- Zygo Interferometry

- UV, VIS, IR Spectrophotometry

- Birefringence

- Homogeneity

- Product Testing and Certification Reports Available

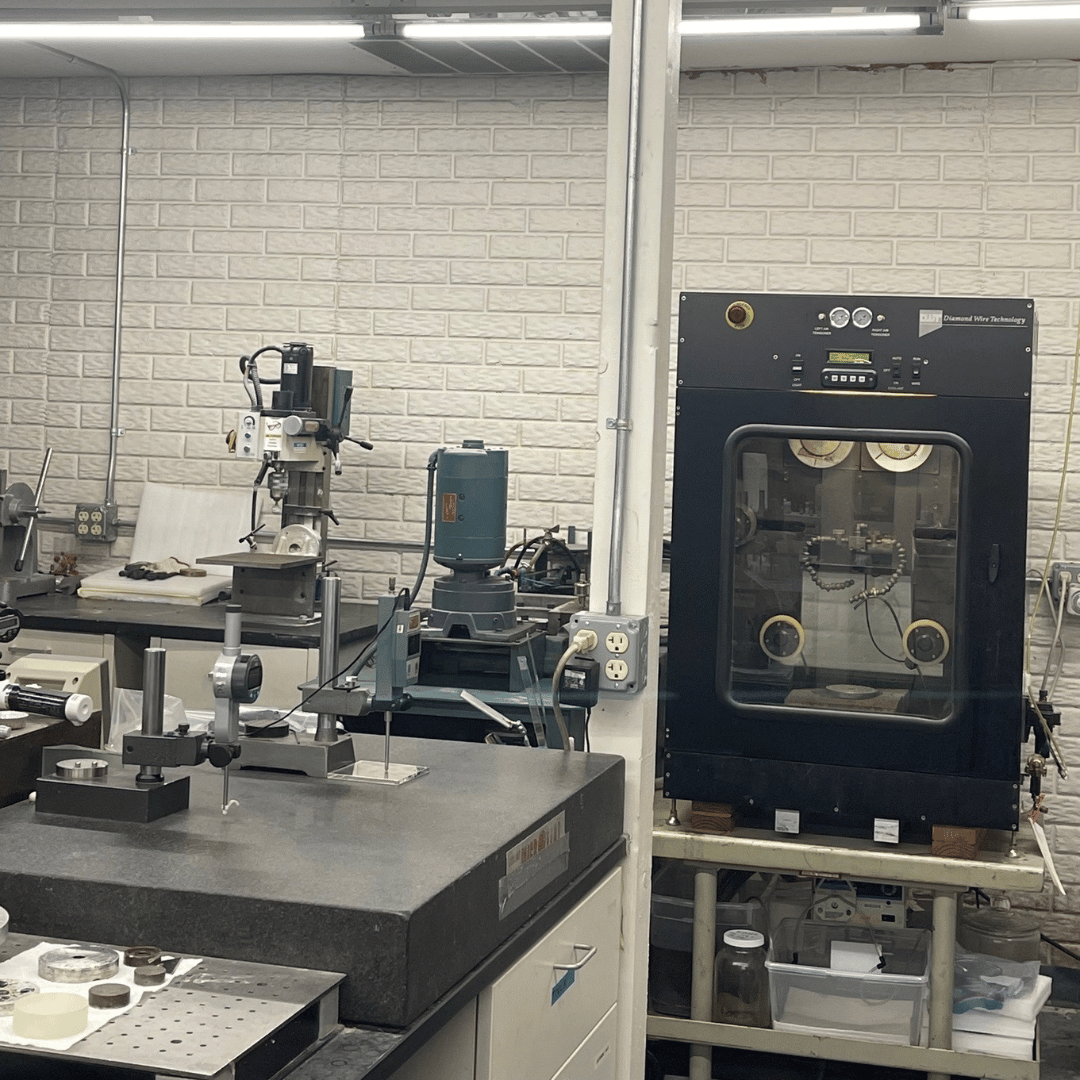

Cutting / Processing

- Diamond wire saw slicing and cutting

- Random and specific crystalline orientation

- <111>, <100>, C-axis,

y-cut